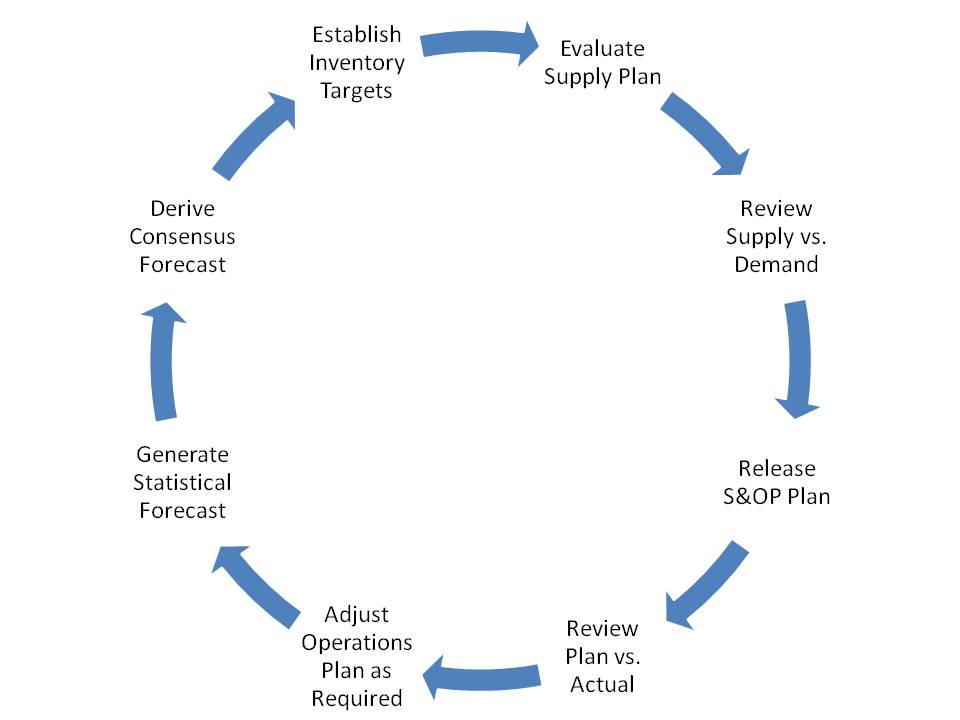

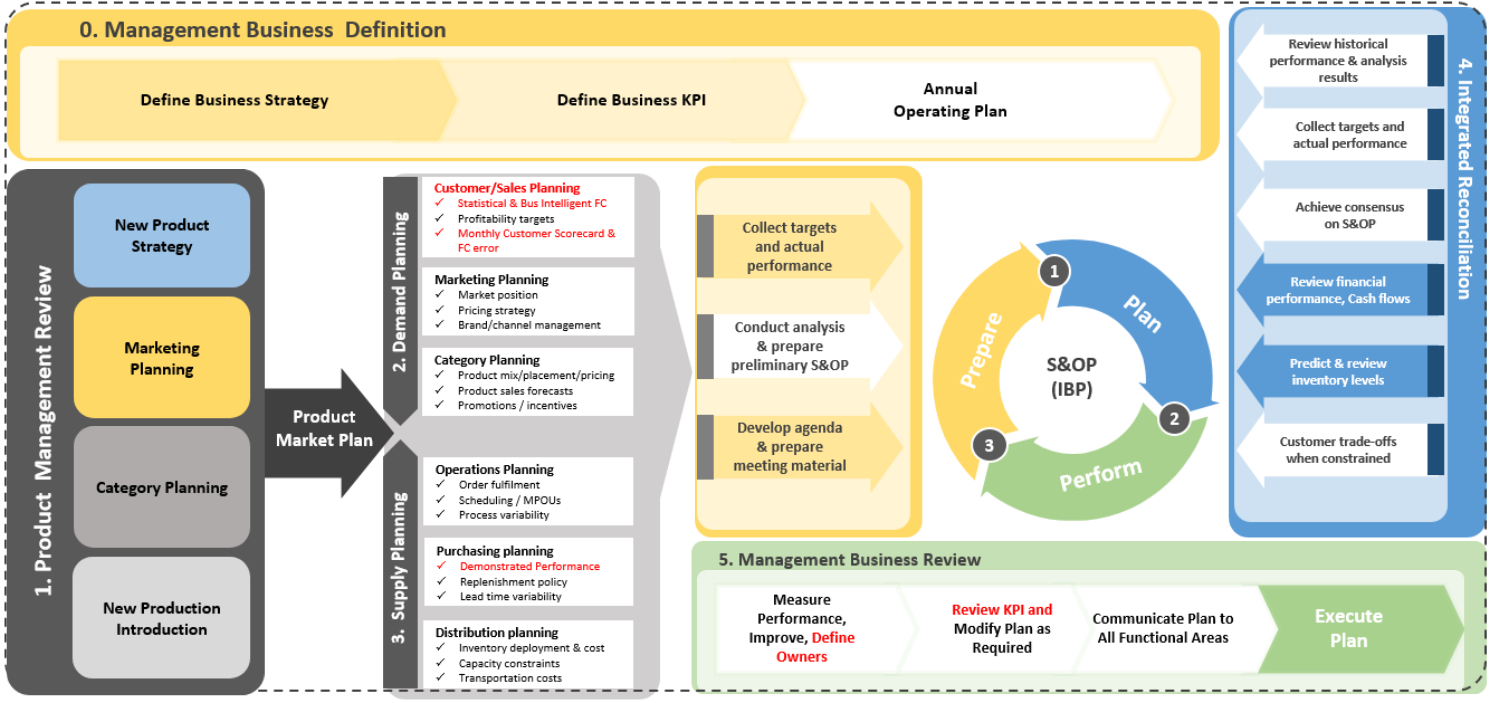

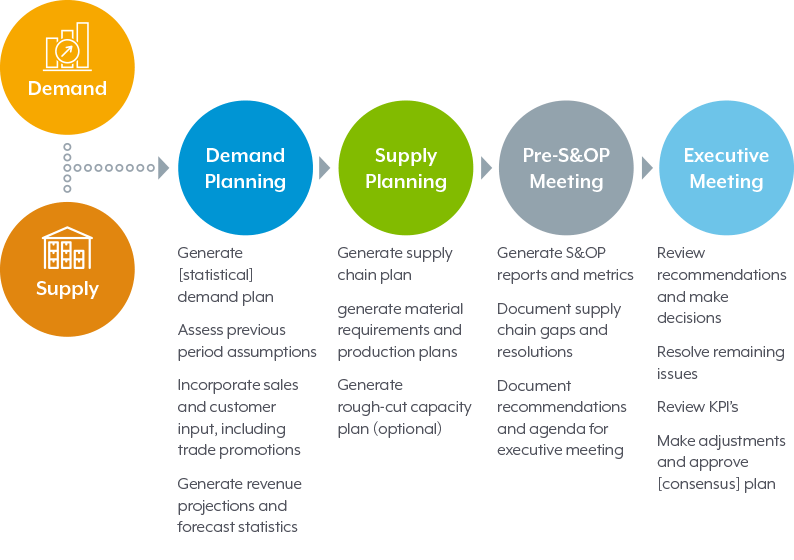

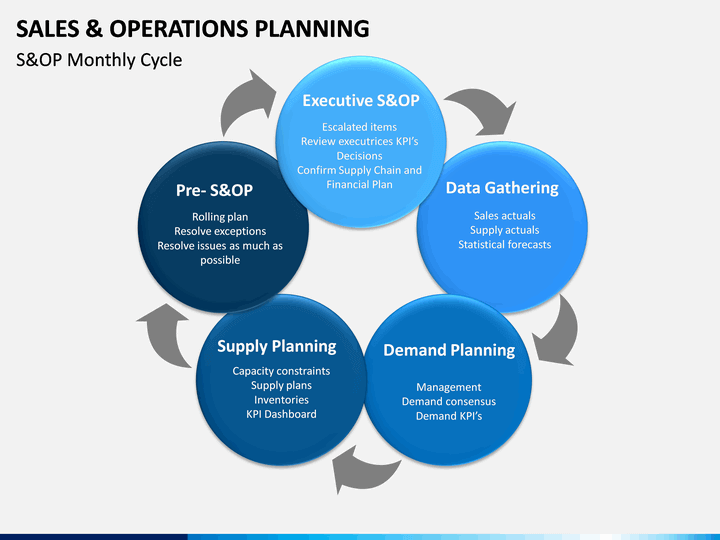

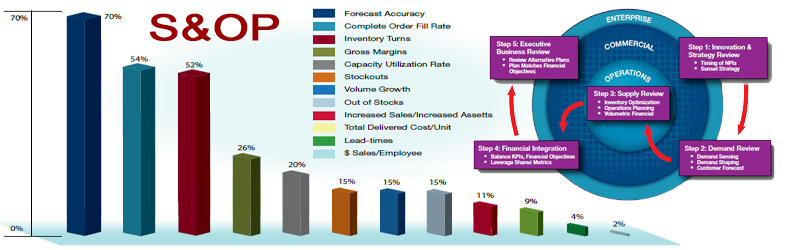

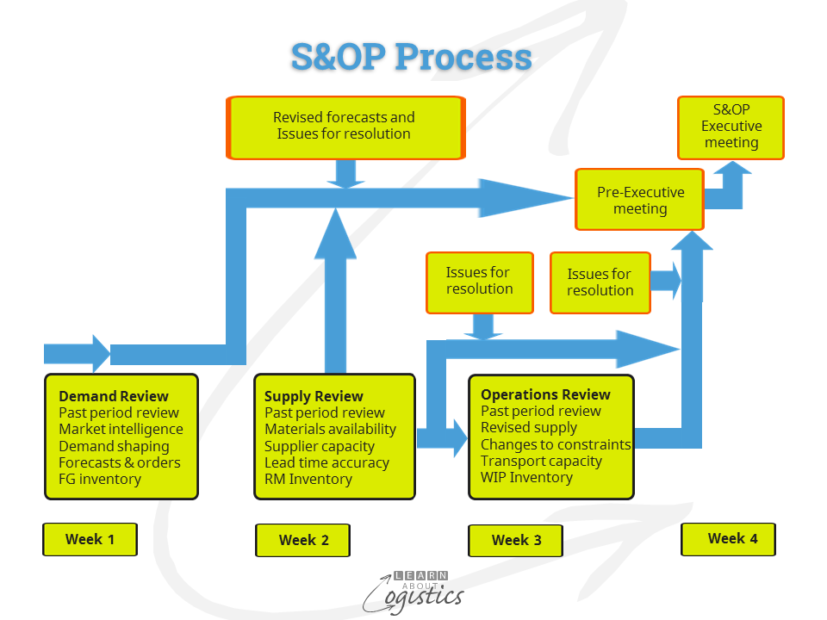

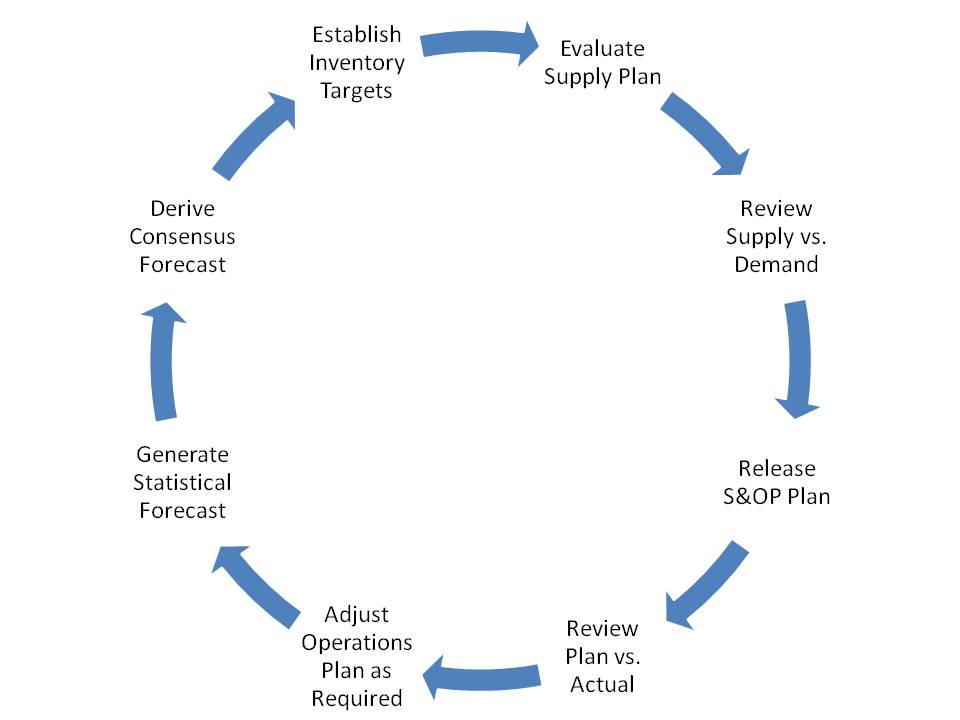

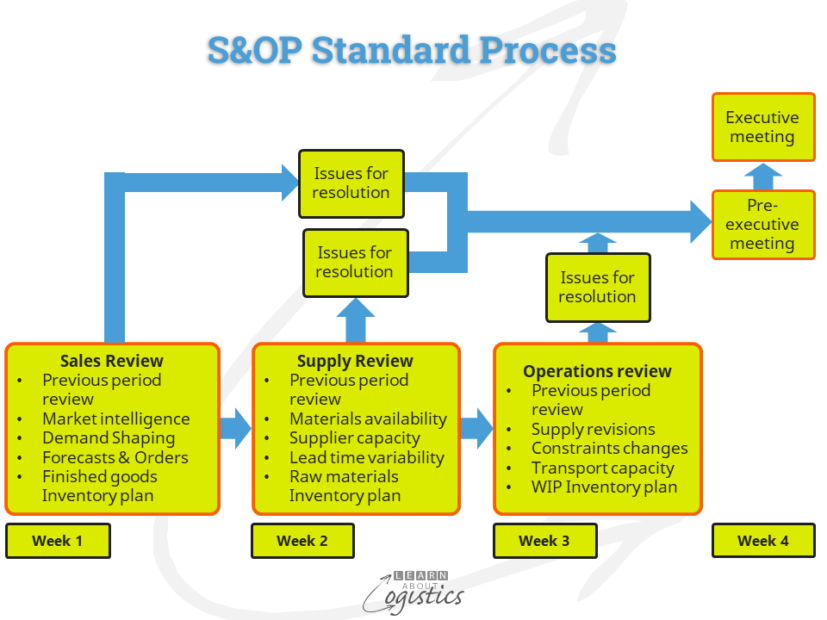

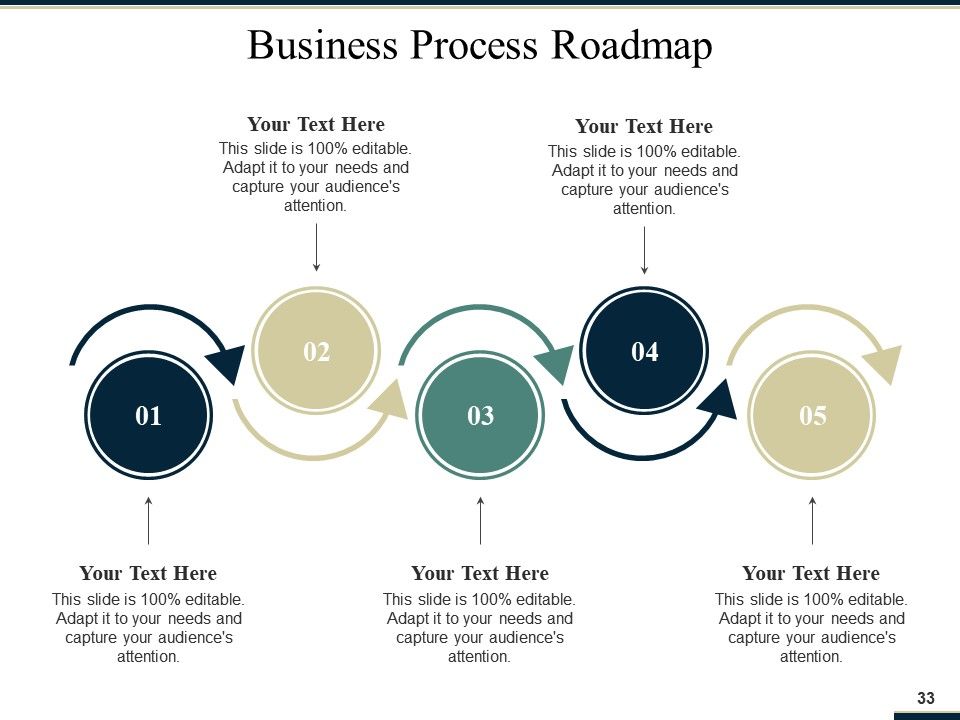

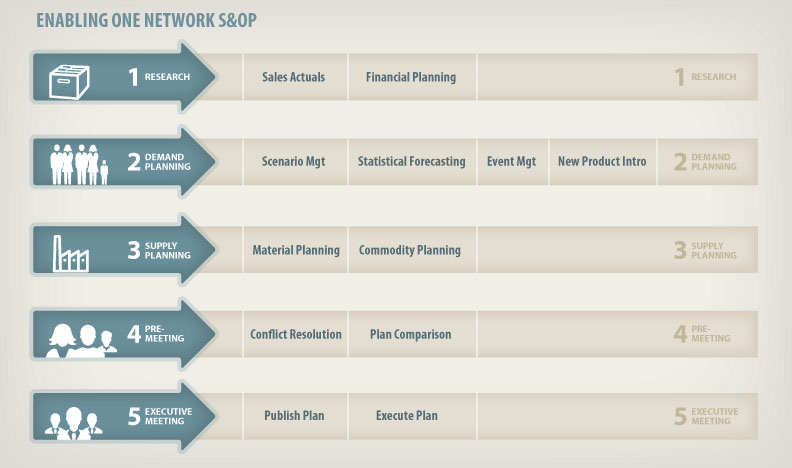

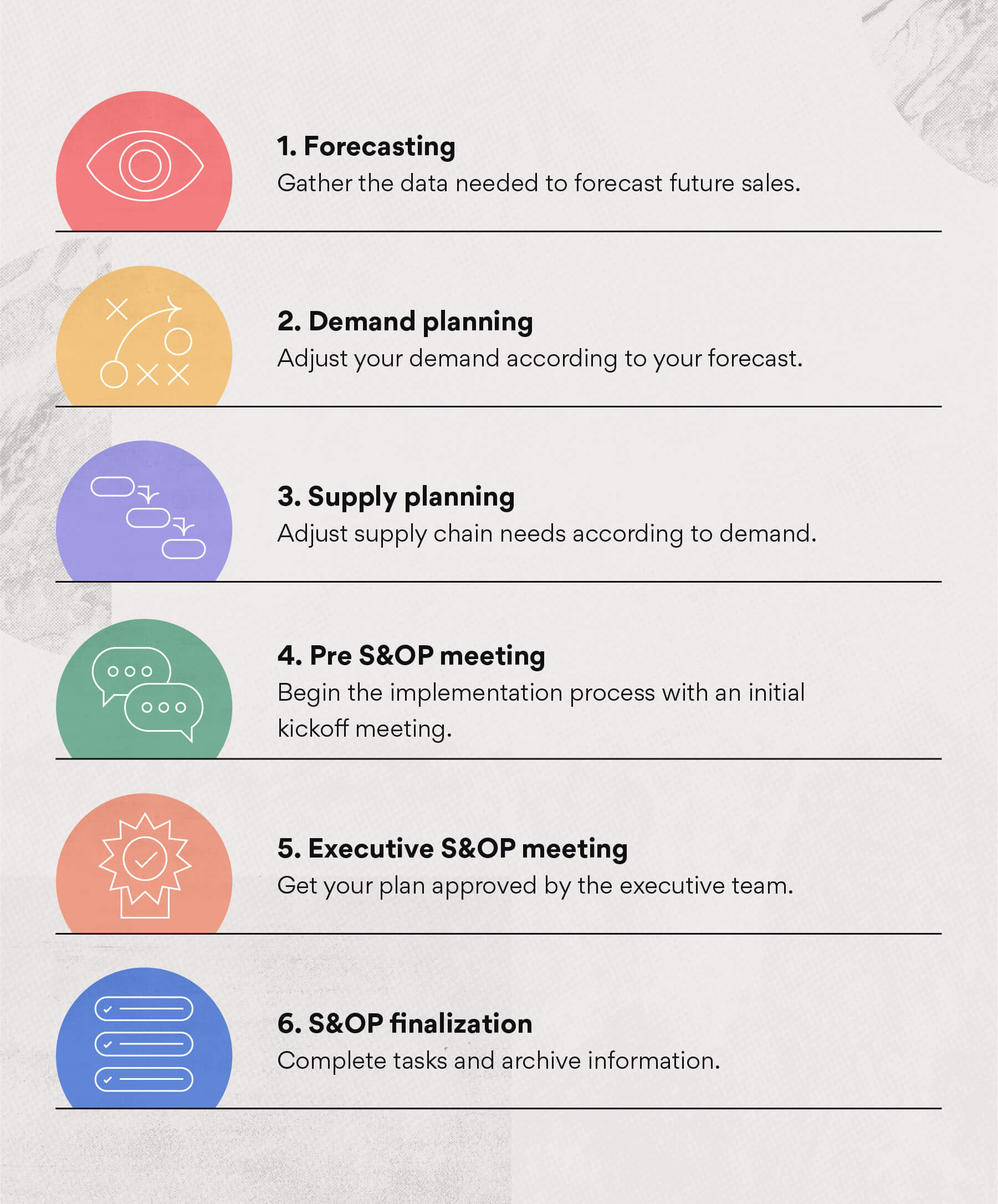

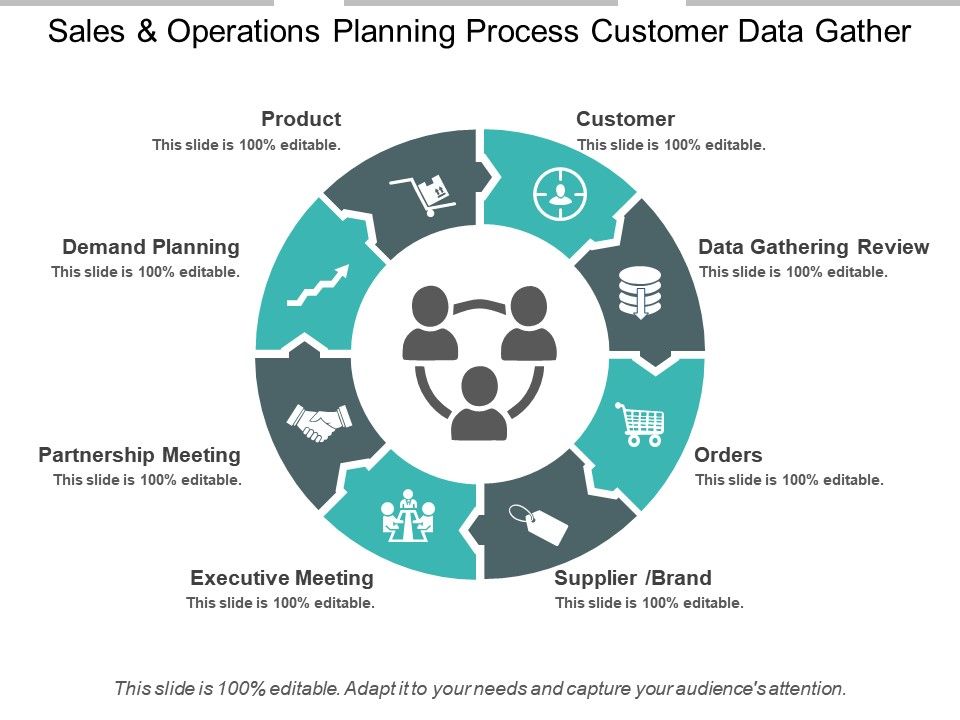

The first step for the supply chain planning leader is to identify the S&OE content in the S&OP process and move it to a separate agenda As a rule of thumb, anything that covers the nearterm horizon, commonly 0 to 3 months, is S&OE It deals with all the issues stemming from actual demand and supply — the reality of supply chain that isThe S&OP cycle consists of six major building blocks Mature organizations should tackle all of these steps of the S&OP process The key to success is to start of with what you have and build from existing processes S&OP Demand Planning Data Gathering & Setup (Analysis, Exception Reporting, Statistical Models, Data Aggregation) Routine Forecasting Cycle (Demand Change Reviews, Sales History and Future Forecast Adjustments, Unconstrained Forecast) Monitor & Improve Forecast Accuracy (Forecast Accuracy KPI, Forecast Value Added from Business Intelligence) Sales & Operations Planning Process Inventory Plan

S Op Process Impacts Excess Finished Goods And Operational Efficiency Hawkeyeconsultingadvisors

S&op planning cycle

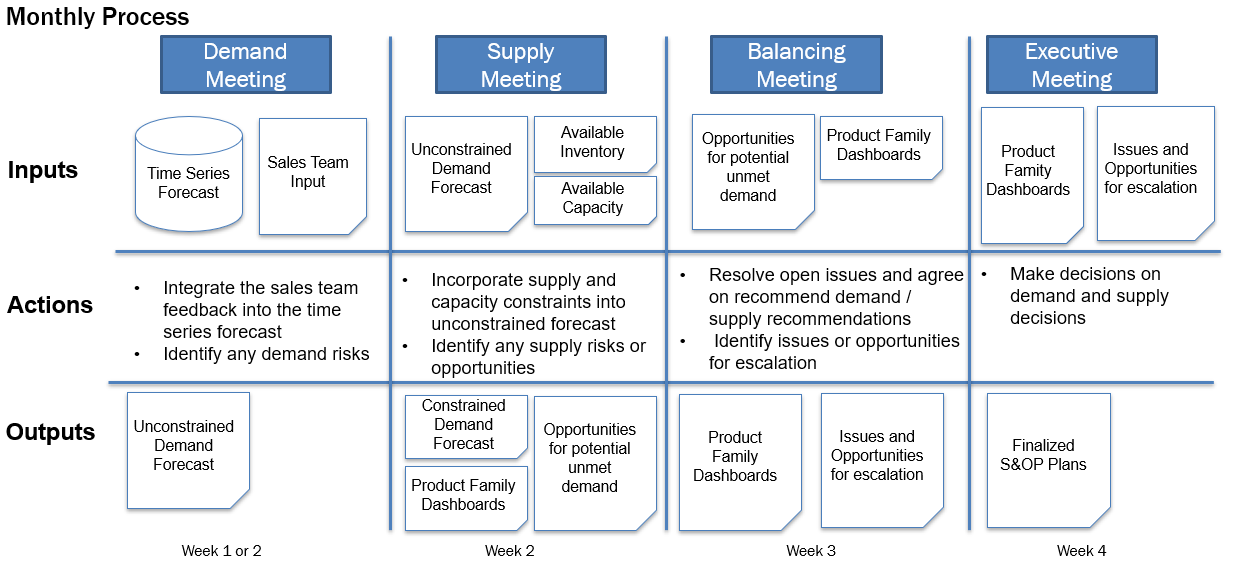

S&op planning cycle- The demand consensus meeting is one of the most important steps in sales and operations planning (S&OP), with the resultant demand plan serving as a critical input for all other S&OP process meetings Without a demand plan as a starting point, not much else can happen in the cycle There would be no supply and demand balancing exercise, plan valuation, or scenario planning The importance of S&OP in Trends in personalization and fast shipping will require planning that goes beyond supply and demand It's , and the pressure is rising to move products through more channels in less time The challenge requires more careful planning Sales and operations planning (S&OP) has been talked about since the

Chapter 14 Aggregate Sales And Operations Planning Lecture

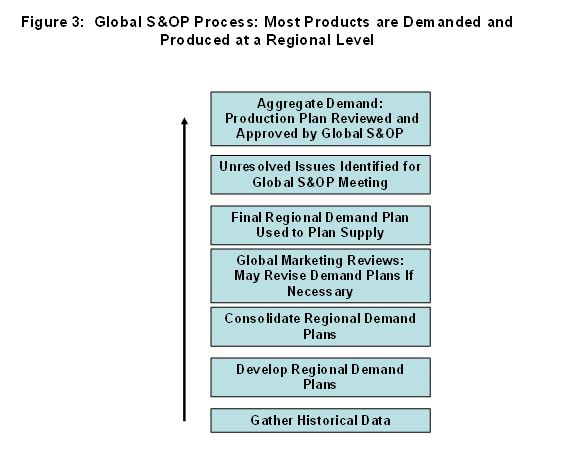

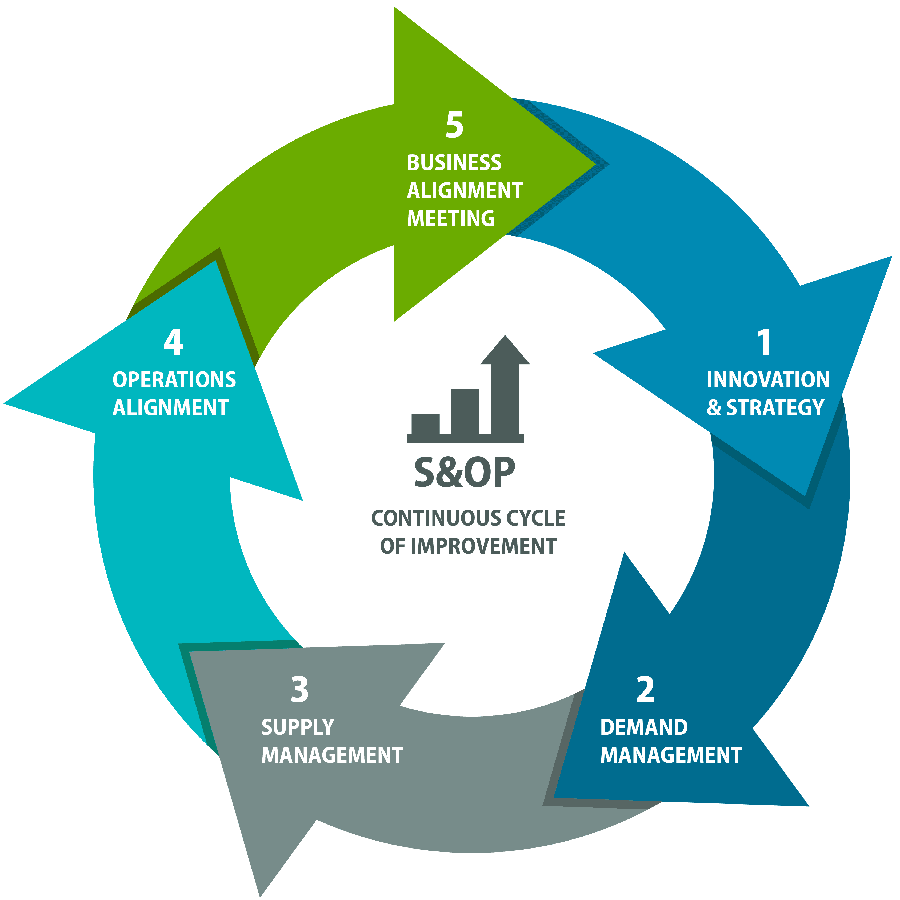

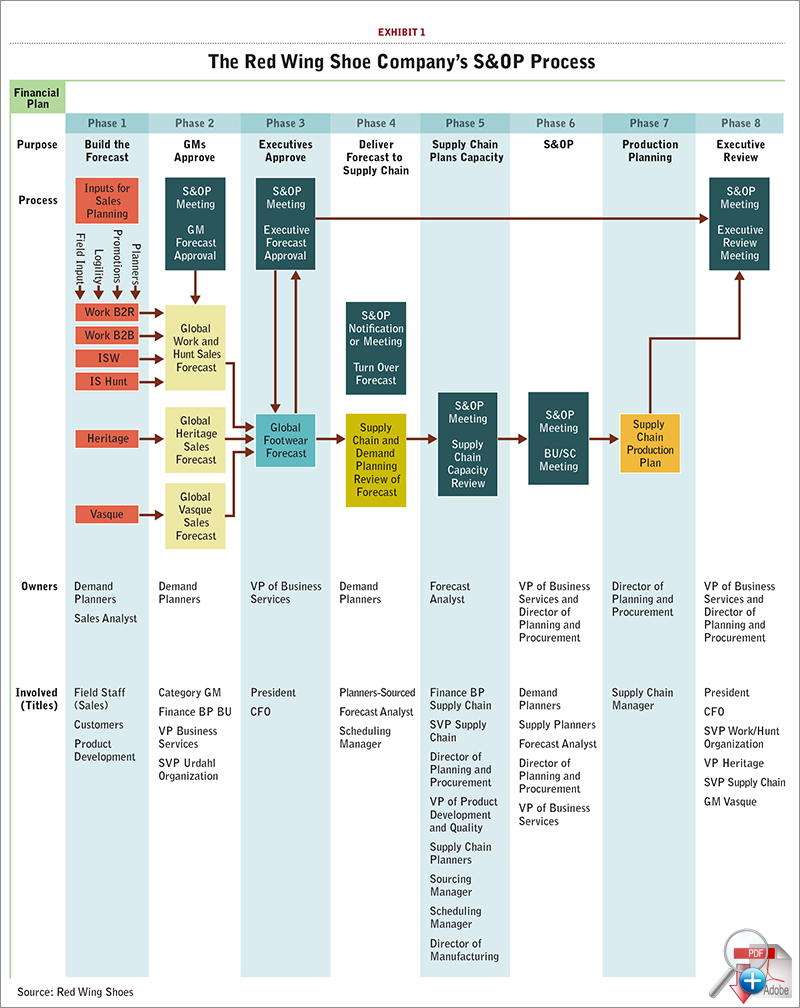

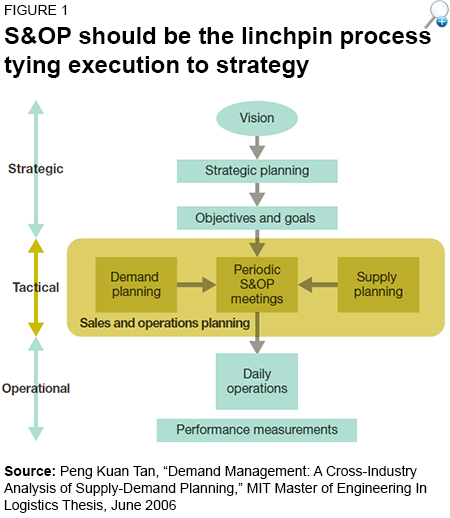

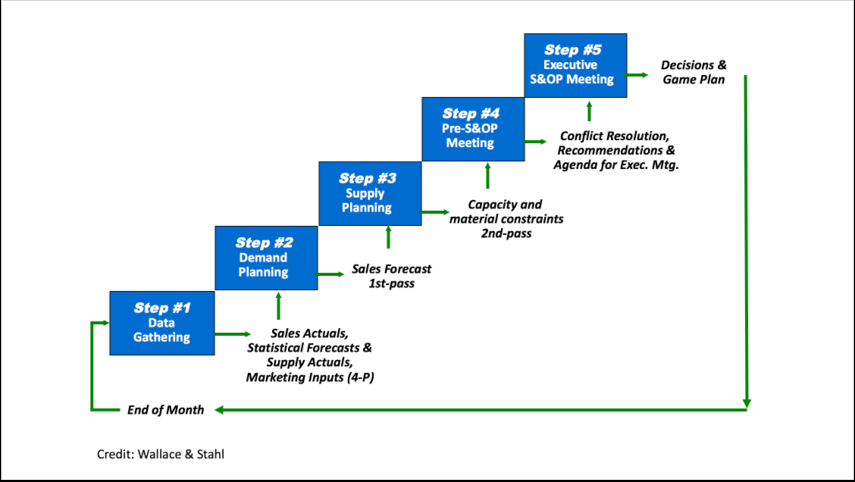

Komoot's route planner for cycling and mountain biking trips will plan a cycle route based on the type of bike you intend on using Whether road, touring or mountain, just select the appropriate sport in the bike route planner menu and komoot's route planner for S&OP gives management the ability to direct its business to achieve a sustainable competitive advantage The overall objective of S&OP is to arrive at a business "Game Plan" to help manage and allocate critical resources to meet the needs of the customer at the lowest cost S&OP is a fivestep process as illustrated in Figure 1Implementing Sales and Operations Planning (S&OP) In our knowledge article What is S&OP?, we explained what sales and operations planning (S&OP) is and its many advantagesTo sum up, S&OP is the creation of a unified, consensusbased business plan that enables organizations to control inventory costs while vastly improving service levels

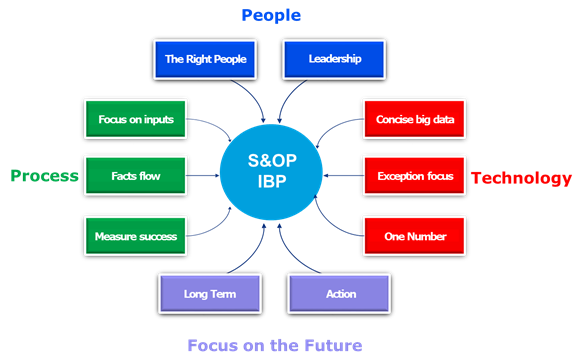

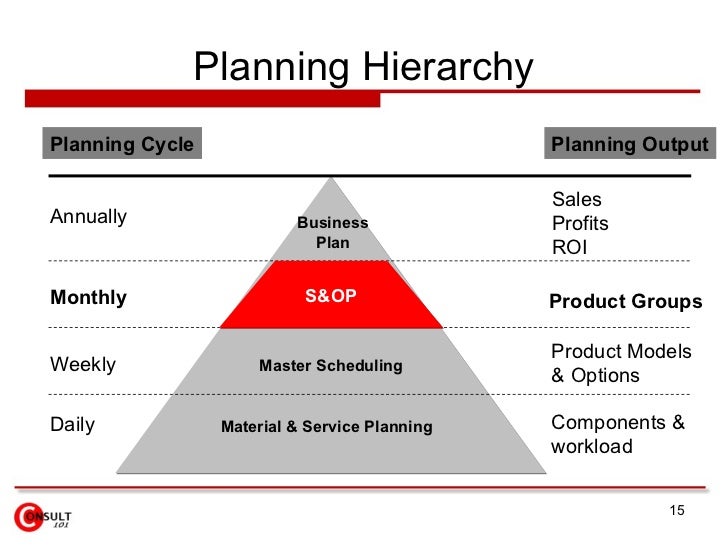

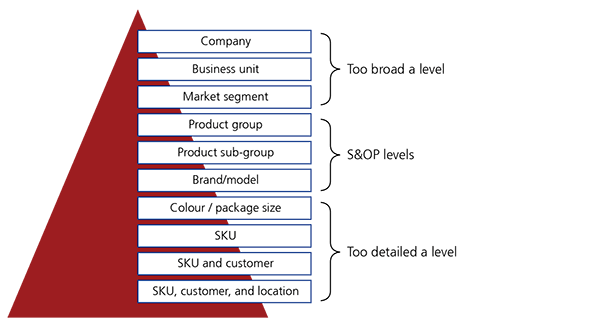

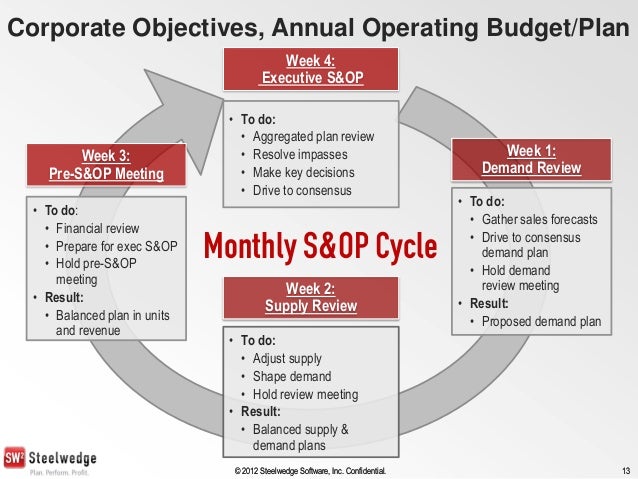

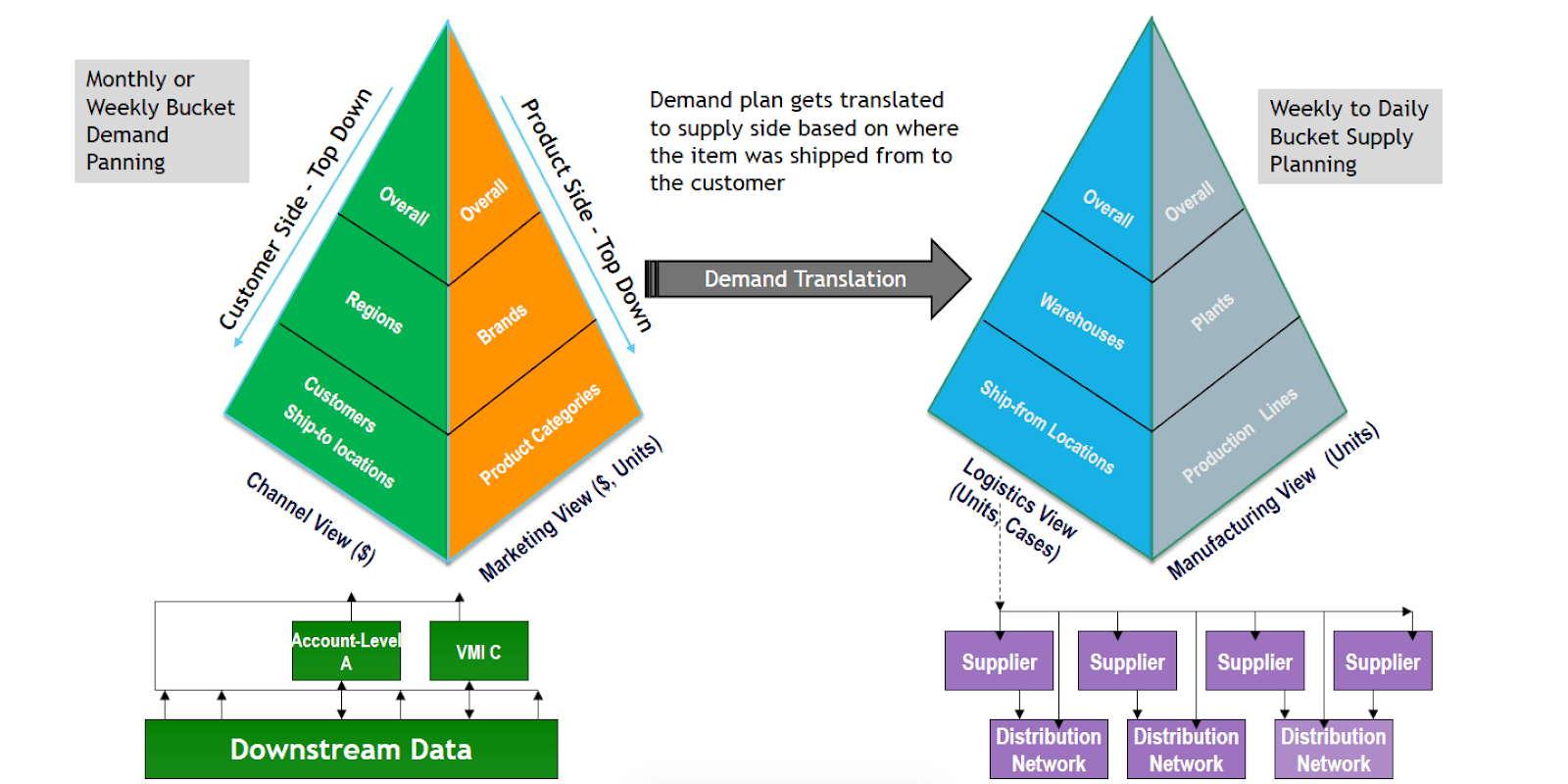

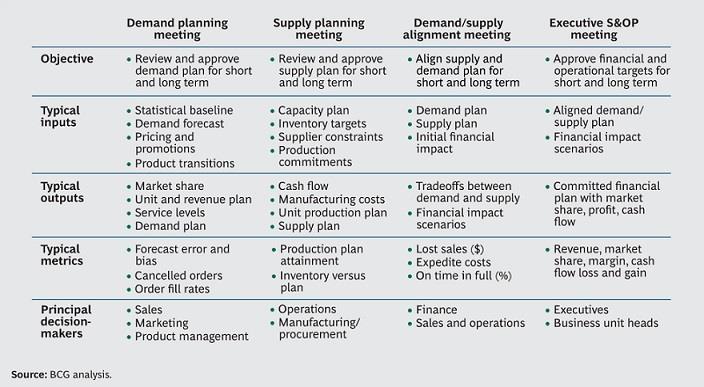

Let S&OP drive your business Companies need a clear approach to balance supply and demand Sales & Operations Planning (S&OP) (also known as IBP, or Integrated Business Planning), will increase alignment in your company your planning teams will be better aligned with your sales teams S&OP is a structured, processoriented and multidisciplinary approach that ensures a Each month or planning period, the S&OP demand and supply planning process follows a very specific linear work flow as outlined in this article Setting a planning hierarchy is a critical part of generating appropriate forecasts The demand planning hierarchy is top down one to many within the sales level and also within the product levelBe familiar with the S&OP processWhat Is Sales and Operations Planning (S&OP)?

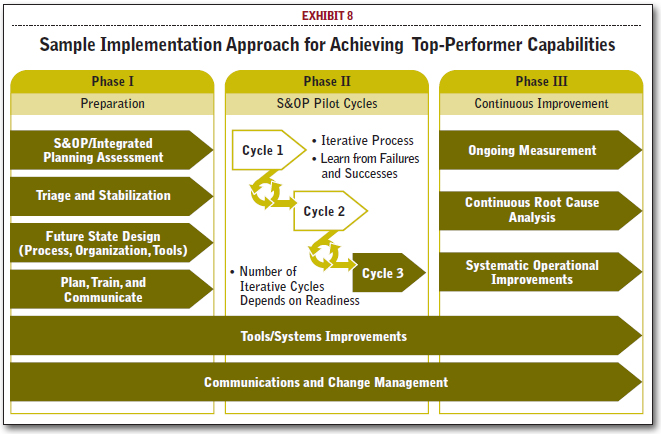

To accomplish the demand and supply balance Sales and Operations Planning Steps to S&OP There are two distinct phases to S&OP 1) process design, and 2) process conduct In the design phase, all of the technical workings are engineered, and in the conduct phase S&OP is used as a business management process The following 10 steps& Operations Planning (S&OP) is now an endeavour that is equal parts science and art With the experience of deploying S&OP initiatives across the Southeast Asia region, this publication presents five planning hurdles that pharmaceutical companies should focus on, and the corresponding strategies to overcome them (see Figure 1)S&OP production plans by family become inputs to the Operations planning tool

What Is S Op Sales And Operations Planning Sap Insights

Software For Sales Operations Planning In Europe Supply Chain Movement

S/OP Planning Drive monthly S/OP Planning process for EU sites by running and chairing S/OP meetings as per defined cycle Running site S/OP model to generate optimal supply plan based on the sales forecast received from Commercial Resolve significant and/or critical supplydemand imbalances or develop plans to do so S&OP although simple in concept is very difficult to implement well Check this list of the essentials during your next S&OP cycle and if you can tick all the boxes, you're doing a good job and can move on to adding more KPIs and reports that ensure your S&OP process is strongly aligned to your strategyAn Annual Operation Plan is based upon the yearly planning cycle and should consider financial budgets of an organization and future uncertainties predicted throughout a projected period Used as an effective planning tool an Annual Operation Plan incorporates goals and objectives throughout relevant facets ensuring cohesion amongst colleagues and departments alike

Sales And Operations Planning Report Do You Get Surprises

Dp Vs S Op Process Flow

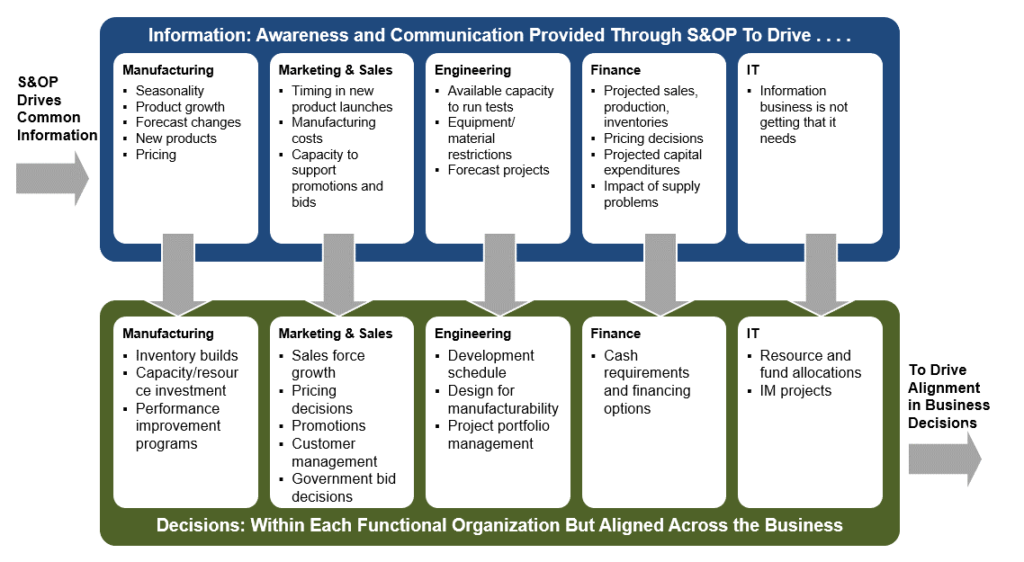

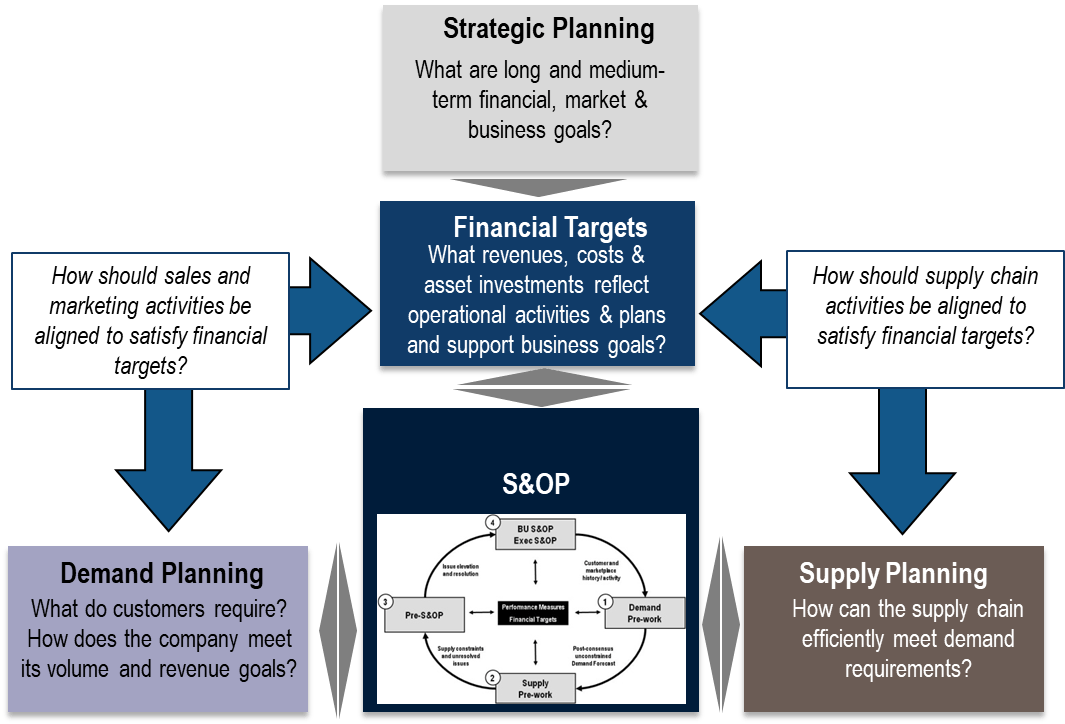

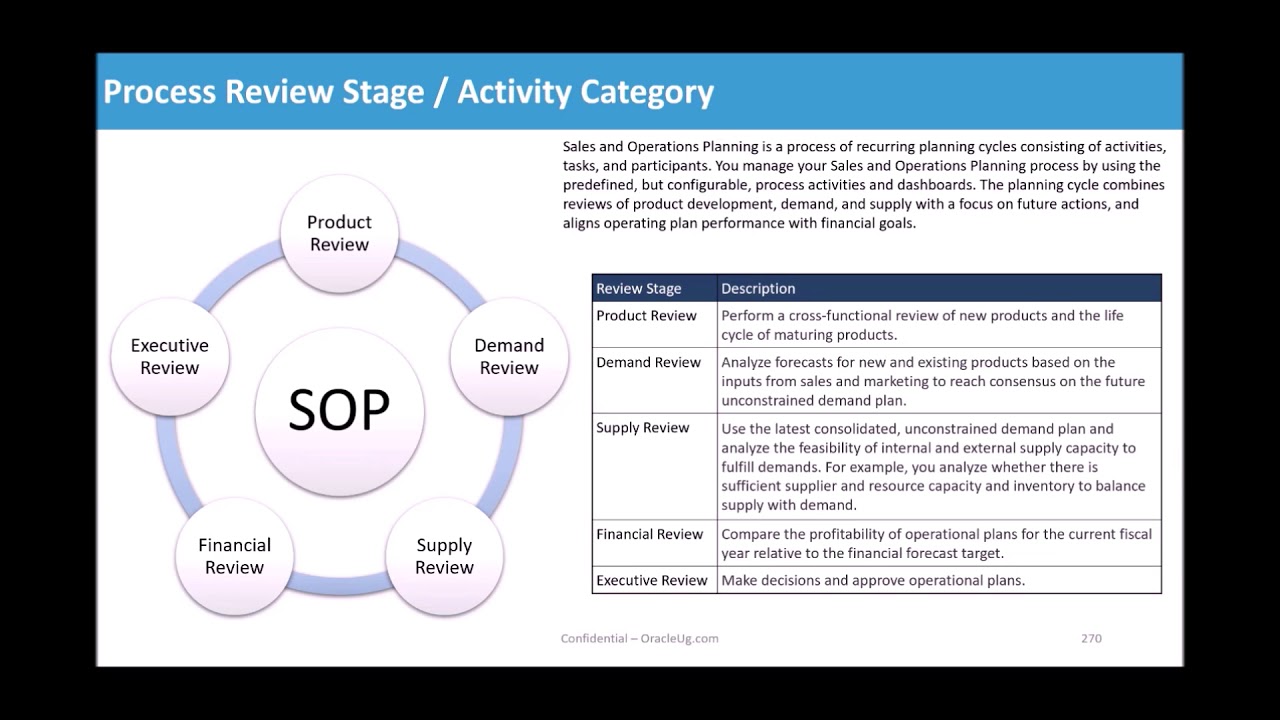

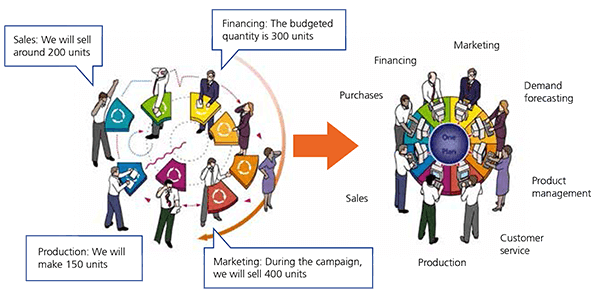

S&OP deals with the continuous change that occurs in the business and is a process to effectively manage ongoing change In practice, it is called a replanning process S&OP is owned by the GM or CEO It is a crossfunctional process and includes all the functions of the company Correctly implemented, it is a demand and strategydriven processSales and operations planning is an aspect of supply chain planning whose goal is the creation of a unified, consensusbased business plan It draws input from an organization's key functional areas, including sales, marketing, manufacturing, distribution, and finance The S&OP process, then, is integral to effective business planning, both in the long term and shorter term S&OE often gets rolled into S&OP because it can be seen as an extension of S&OP The S&OE process, however, focuses on a much more immediate time frame, usually zero to three months Again, this period may vary in different industries

S Op Implementation Roadmap Roadmap Procurement Management Future Plans

S Op A New Frontier For Supply Chain Resilience 05 14 Cscmp S Supply Chain Quarterly

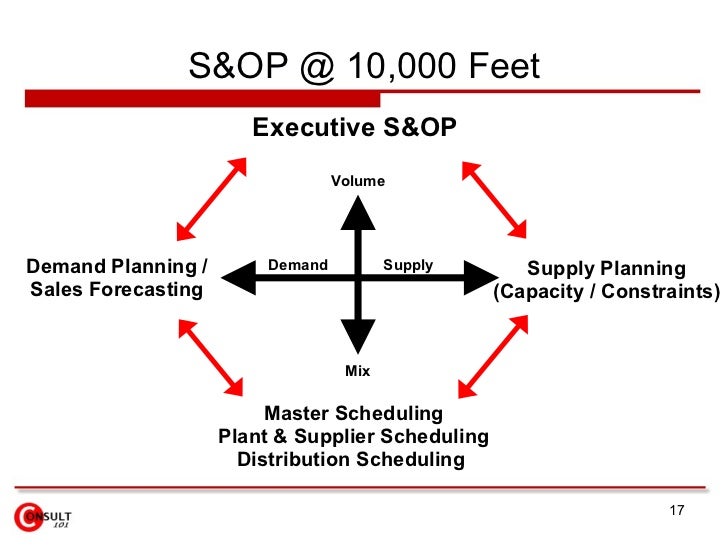

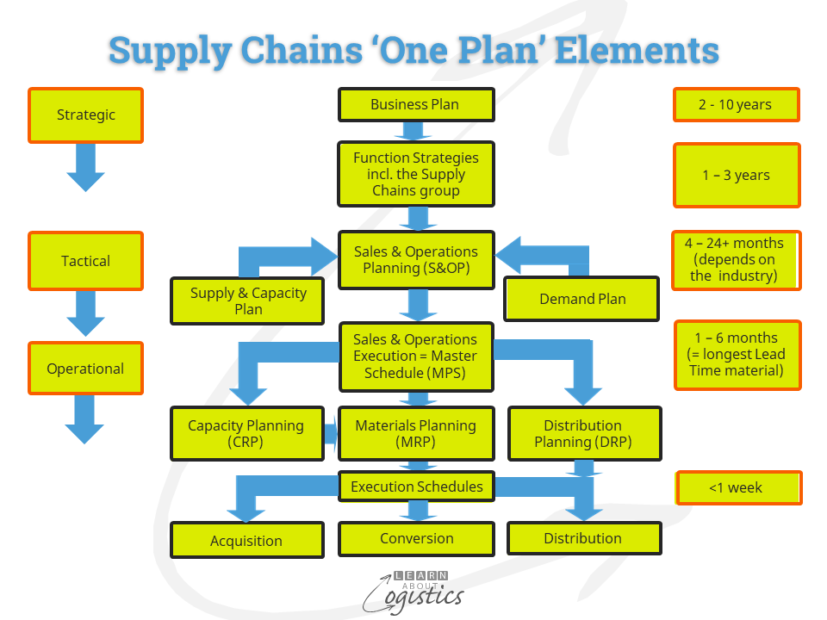

S&OP Relationship with other Plans 15 Planning Hierarchy Business Plan Master Scheduling Material & Service Planning Annually Monthly Weekly Daily Sales Profits ROI Product Groups Product Models & Options Components & workload Planning Cycle Planning Output S&OP 16S&OP practice may not be aware of differing time horizons or planning horizons represented by departments Different departments, such as finance, research and development (R&D), production, marketing, and senior management, may have different planning horizons that make S&OP planning difficult to reconcile Forecast Trust Operational planning – Rolling twelve months, reviewed monthly Translates tactical plans into specific objectives and confirms activities and timings through shortterm plans and execution Goal of S&OP process The primary goal of the sales and operations planning process is to facilitate the flow of information between demand and supply

Sales Operations Planning Omnics

5 Reasons Why Sales And Operations Planning Is Important Scmdojo

Sales and operations planning (S&OP) is a popular process that aligns a company's diverse functions while balancing supply and demand S&OP gives executives a comprehensive overview of the business so they can grasp where it stands (in all its complexity) This allows them to continuously match highlevel strategy with daytoday operationalRealtime information for S&OP planning cycles Sensor and DemandDriven Supply Planning Sensor data predict at which point in time products will become available and change the current way of planning Multiecholon stock level optimization stabilizes demand disruption within the supply chain Both enable you to move The planning cycle operational planning, readiness & effectiveness This best practice framework is the basis for successful planning teams Learn what the bestinclass looks like and find out who has demonstrated these planning qualities in our recent Standards Benchmarking Assessments and Accreditation

Sales And Operations Planning S Op Logistiikan Maailma

What Is S Op How S Op Works Demand Planning Com

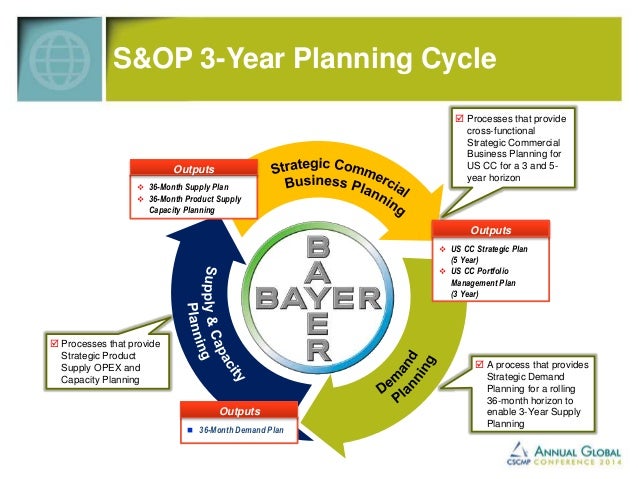

The Executive S&OP planning cycle is monthly, with provisions for midperiod revisions when major changes occur Executive S&OP is an aggregate planning tool It focuses on aggregate volumes, and only rarely looks at issues of mix, ie individual products, stock keeping units, customer orders and so onInterest in S&OP The increased interest led me to write a column on the S&OP process in the Summer 02 issue of the Journal of Business Forecasting, which was titled, "You Need Sales and Operations Planning" In this issue's column, I'm kicking off a threepart series on the S&OP process Coverage includes (in this order) 1) the Here is a quickstart guide on how to implement S&OP Process A robust S&OP process description which is deployed with discipline and consistency Systems Providing effective and wellintegrated systems to facilitate execution of a regular monthly planning cycle People Building capability across the enterprise functions and creating the

S Op Sales And Operations Planning And Sco

Sales And Operations Planning Myths Part 3 Supply Chain 24 7

Sales and Operations Planning (S&OP) Sales and operations planning (S&OP) is a business management process where leadership and executive teams meet to ensure each business function is aligned to balance supply and demand S&OP requires crossorganizational collaboration to create detailed forecasts for predicted sales S&OP plans are reviewed by product family, using the common unit of measure This provides a consistent communication base across all functions and entities; Amazon's Planning Process The Amazon planning process is divided into a biannual process dubbed OP1 (Operating Plan) and OP2 OP1, which happens around June, is a mandatory sixpage document produced by every team's Product Manager, addressing the following questions What outcomes did you achieve last year, in comparison to what you

Sales Operations Planning Consulting Supply Velocity

Sales And Operations Planning S Op Transform Your Business

1 QA 1 Unpacking the planning cycle Quality Area 1 Unpacking the planning cycle This resource is adapted from ACECQA's blog, 'We hear you' https//wehearyouacecqagovau/ Many educators find Element 131 – Each child's learning and development is assessed or evaluated as part of an ongoing cycle of observation, analysingPart of a Sales and Operations Planning (S&OP) process 4 Performance measurements Larry Lapide, 06 Page 10 1 Forecasting Organization A integrated approach is driven by a stakeholder organization that is chartered Life Cycle Î Uses prior history S&OP is a structured planning process, based on a monthly cycle The objective is to improve the balance between future demands for the market's products and services, the organisation's resources and the supply of materials and services And, of course how the plan will be financed Implementing the S&OP process

Cscmp 14 Bayer Putting The S Back In S Op

Ready To Upgrade Your S Op Process For Industry 4 0

S&OP, or sales & operations planning, is a monthly integrated business management process that empowers leadership to focus on key supply chain drivers, including sales, marketing, demand management, production, inventory management, and new product introduction With an eye on financial and business impact, the goal of S&OP software is toAn Executive Whitepaper Successful Sales and Operations Planning in 5 Steps LOGILITY VOYAGER SOLUTIONS wwwlogilitycom 2 Executive Overview The Sales and Operations Planning (S&OP)1 process is well known and understood in the world of supply chain managementS&OP Processes Planning Objectives of S&OP ‐ S&OP supports and measures the progress of the entire organization in meeting the enterprise's business plan ‐ S&OP ensures that the strategic plans developed in the business plan are realistic and can be successfully executed before they are passed to tactical planning

A Comprehensive Overview Of Sales And Operations Planning S Op

Sap Integrated Business Planning Ibp Sales And Operations Planning 18 Sap Blogs

S&OP, Integrated Planning and Supply Chain Excellence Agenda • Part I The potential and promise of S&OP • Short life cycles • 5000 new products annually • 37% of its production is for orders ofThe Plandocheckact cycle (Figure 1) is a fourstep model for carrying out change Just as a circle has no end, the PDCA cycle should be repeated again and again for continuous improvement The PDCA cycle is considered a project planning tool1 S&OP in the Planning Cycle Bạn đang xem bản rút gọn của tài liệu Xem và tải ngay bản đầy đủ của tài liệu tại đây (3853 MB, 504 trang )

1

Achieve Excellence In Sales And Operations Planning Sapinsider

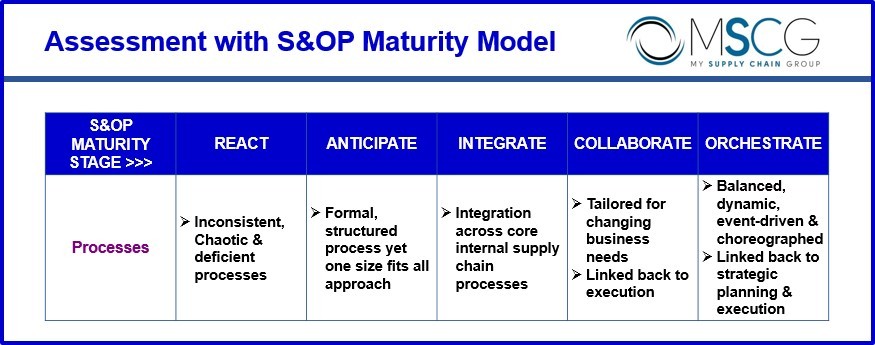

S&OP IS A JOURNEY Efficiency Effectiveness Optimization Stage 1 Reacting Stage 2 Anticipating Stage 3 Capable S&OP Stage 4 Optimized Planning Stage 5 Integrated Business Planning Maturity Levels based on Gartner's recommendations • Business plan drive forecast • Shortterm forecast • Aggregate S&OP Data • Offline Demand / Supply

Sales Role In Sales And Operation Planning Demand Planning The Sales Process Blog

What Is S Op How S Op Works Demand Planning Com

S Op Process

Sap Integrated Business Planning Ibp Sales And Operations Planning 18 Sap Blogs

1

Sales And Operations Planning 4 Fundamental Concepts Sourcecodematrix

Achieve Excellence In Sales And Operations Planning Sapinsider

Sales And Operations Planning Relex Solutions

Chapter 14 Aggregate Sales And Operations Planning Lecture

Implementing A Sales Operations Planning S Op Process Plex Demandcaster

Who Should Own Sales And Operations Planning I Kinaxis

Demand Planner Terranova Strategic Hr Partners

Integrated Business Planning Ibp S Op Evolution Agile Innovation

Fixing An Overly Complicated Sales And Operational Planning Process Supply And Demand Chain Executive

Improving Profitability With Sales Operations Planning Magellan Consulting Group

Sales And Operations Planning Powerpoint Template Sketchbubble

The Sales And Operations Planning Process In The Context Of Various Download Scientific Diagram

What Is S Op How S Op Works Demand Planning Com

S Op Process

2

S Op Process

Sales And Operations Planning Overview Chapter 1 Rb

1

What Is S Op The Origins Use And Value Of Sales Operations Planning

Sales And Operations Planning Business Forecasting Taruna Nagpal

The S Op Journey Beyond The Supply Demand Match Organization And Ownership For The Demand Planning Process Aberdeen Strategy Research

Sales And Operations Planning Cycle Chainsequence Inc

Oracle Cloud Applications Supply Chain Planning Intro To Sales And Operations Planning Youtube

3 Primary Components Of Sales Operations Planning People Process And Technology Supply Chain 24 7

Top Performer Benefits Of Effective Sales Operations Planning Supply Chain 24 7

Supply Chain Graphic Of The Week The S Op Process

Sales Inventory Operations Planning Si Op A Roadmap To Si Op Success Pragmatek Consulting

What Are The Basic Elements Of The S Op Process Quora

S Op Effectiveness Recommendations To Make The Leap Supply Chain Shaman

Sales And Operations Planning Relex Solutions

Implement The S Op Process For Supply Chain Success Learn About Logistics

1

Achieve Excellence In Sales And Operations Planning Sapinsider

Sales And Operations Planning S Op 101 Smartsheet

What Is S Op Sales And Operations Planning Explained Anaplan

S Op Process Impacts Excess Finished Goods And Operational Efficiency Hawkeyeconsultingadvisors

How S Op Improves Your Organization Tmc Fr

S Op Five Steps To Get Started Supply Chain Shaman

Road Map Of Integrated Business Planning For Supply Chain Part Ii The 5 Ps Of S Op Maturity My Supply Chain Group

Top 11 Sales And Operations Planning S Op Software In 21 Reviews Features Pricing Comparison Pat Research B2b Reviews Buying Guides Best Practices

Gartner Blog Network

Pdf Sales And Operations Planning S Op An Overview

What Is One Plan S Op Arkieva

Sap Integrated Business Planning Ibp Sales And Operations Planning 18 Sap Blogs

A Common S Op Process For Your Business Helps Planning Learn About Logistics

Sales And Operations Planning Powerpoint Presentation Slides Presentation Powerpoint Templates Ppt Slide Templates Presentation Slides Design Idea

Sales Operational Planning S Op Versus Integrated Business Planning Ibp Supply Chain Link Blog Arkieva

S Op More Important For Planning New Era Supply Chains Learn About Logistics

Sales And Operations Planning Powerpoint Presentation Slides Presentation Powerpoint Templates Ppt Slide Templates Presentation Slides Design Idea

S Op Introduction

Sales And Operations Planning Adroit North America

Sales And Operations Planning S Op

Supply Planning Processes Options Analytics Oh My Plex Demandcaster

A Comprehensive Overview Of Sales And Operations Planning S Op

What Is S Op How S Op Works Demand Planning Com

Involving Execution Managers With Sales And Operations Planning Supply Chain 24 7

Scielo Brasil A Case Method For Sales And Operations Planning A Learning Experience From Germany A Case Method For Sales And Operations Planning A Learning Experience From Germany

Sales And Operations Planning A Project Manager S Guide Asana

Sales And Operations Planning Relex Solutions

Ultimate Guide To Sales And Operations Planning S Op In 21

Scielo Brasil Avaliacao Da Maturidade Do Processo De S Amp Op Em Uma Empresa De Material De Escrita Um Estudo De Caso Avaliacao Da Maturidade Do Processo De S Amp Op Em Uma Empresa

S Op Made Practical The European Business Review

Integrating The S Op Process Go With The Flow Online Sales Guide Tips

Smoother Execution Through S Op Logistics Management

S Op The Evolving Supply Chain Lifeline Supplychainomics

Sales And Operations Planning Explorescm

Sales Operations Planning Why Is S Op Important

The 5 Most Common Sales Operations Planning Mistakes And How To Avoid Them Supply Chain 24 7

Good Sales And Operations Planning Is No Longer Good Enough Bain Company

Sales And Operations Planning Process Customer Data Gather Powerpoint Slide Templates Download Ppt Background Template Presentation Slides Images

Sales Operations Planning Scpi

Top Performer Benefits Of Effective Sales Operations Planning Supply Chain 24 7

What Is Sales And Operations Planning S Op Plex Demandcaster

Top Performer Benefits Of Effective Sales Operations Planning Supply Chain 24 7

Oracle Demantra Sales And Operations Planning User Guide

Getting To Grips With Sales And Operational Planning Bloor Research

Sales And Operations Planning Process Self Assessment

What Are The Basic Elements Of The S Op Process Quora

S Op Software Sales And Operations Planning Qad Dynasys

0 件のコメント:

コメントを投稿